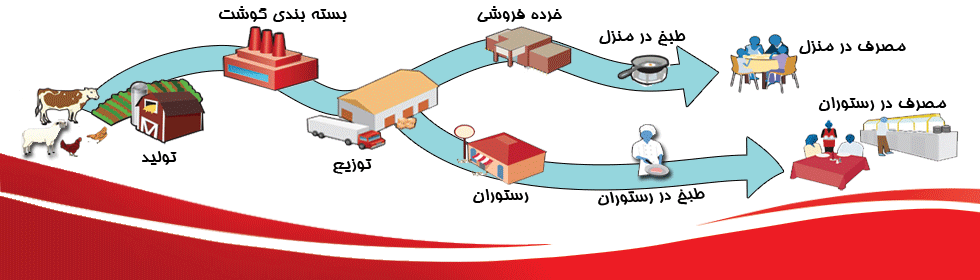

Production and supply

a. Industrial slaughter-house

This vast complex encompasses a slaughter line for heavy weight animals (cows, calf and camels) and some slaughter lines for light weight animals (sheep and ostrich). It is equipped with a pre-fridge with a capacity of 2000 carcasses per each working shift.

b. Red meat packaging hall

1. Primary preparation of the sheep carcass: with the help of highly competent personnel suitably experienced in meat preparation, the sheep carcasses are brought out of the pre-fridge and in the course of various stages they are cut, deboned, packed in luxurious boxes or cartons and marketed.

2. Veal preparation line: with the help of experienced staff, calf carcasses are deboned and marketed in luxurious boxes or cartons of various weights. Having passed rules of hygiene and obtained required health licenses, sheep and calf carcasses are carried to the Red Meat Packaging Complex under the surveillance of veterinary experts by vehicles approved by the Veterinary Organization. They are, then, unloaded under the surveillance of a veterinary expert to be put in the pre-fridge. After a 24-hour time interval, they go through the process of preparation to be supplied to the market.

3. Ground meat production line: observing all rules of hygiene, veal and mutton surplus are entered to this production line to be converted into ground meat in a proper combination by fully automatic equipment. They are, then, packed into luxurious disposable food containers.

c. Packaging hall of animal offal

Different offal of animals (Kale Pacha, tripe, liver, heart and kidney) are extracted and trimmed in this section.